The Krautkrämer CL Go+ precision thickness gauge is a versatile tool in a compact and rugged package. With its intuitive menus and easy-to-use switch pad control, users can focus to make best use...

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726.

Aviation Week Marketplace is part of the Informa Markets Division of Informa PLC

Save this service to your Saved Items and return to it later.

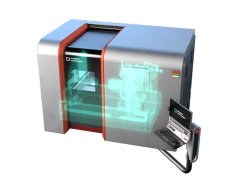

Our Phoenix V|tome|x C is a compact 450 kV CT system with the largest possible scan volume and usable specimen weight especially for production and production-related areas such as production lines and quality assurance laboratories in battery manufacturing, in foundries and in aerospace – a flexible combination of semi-automated, non-destructive inspection and VDI 2630-1.3 specified 3D metrology.

The Phoenix V|tome|x C comes standard with our exclusive 4 MP Dynamic 41|200 next-generation photodiode design industrial X-ray detector. It provides 10x increased sensitivity relative to the state of the art 200 µm pixel size DXR detectors producing 2-3x cycle time increase without image quality impact, making inspections and measurements more efficient and productive. Compared to 16-bit detectors, the optimized 14-bit technology offers the highest efficiency with a dynamic range of 10000:1 and thus saves time in use and also generates less noise in the image. As a premium option, the 100 µm / 16 MP Dynamic 41|100 detector provides a 2x resolution increase without cycle time impact. Detection of 2x smaller defects without an increase of geometric magnification allows for the imaging of large objects at a higher resolution.

View this product at www.bakerhughes.com/waygate-technologies/industrial-radiography-and-ct/industrial-3d-precision-metrology-ct/vtomex-c

The Krautkrämer CL Go+ precision thickness gauge is a versatile tool in a compact and rugged package. With its intuitive menus and easy-to-use switch pad control, users can focus to make best use...

As global technological demands require increased productivity while tightening regulations require ultimate precision to ensure the highest levels of quality and safety, your inspection...

Krautkrämer RokStar’s unique design guarantees enhanced stability during scanner movement. The scanner rides on two steel beams in the primary X direction. All other axes are interpolating indexed...

Driven by advanced analytics to inspect in entirely new ways, the more intelligent Mentor Visual iQ+ borescope uses computer vision to increase probability of detection while reducing inspection...

The V|tome|x M Neo computed tomography solution sets a new standard in flexibility, speed, and detection quality, making it the ultimate choice for a wide range of 3D metrology and analysis...