When PMA companies are tasked with reverse engineering aircraft system components, determining the carbon graphite material grade can be a challenge. Metcar's materials lab is fully equipped to run...

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726.

Aviation Week Marketplace is part of the Informa Markets Division of Informa PLC

Save this service to your Saved Items and return to it later.

Jet engines are meticulously engineered to withstand the most unforgiving conditions known to modern technology. Within turbines, temperatures soar beyond 1,000°F, shaft speeds reach dizzying heights surpassing 30,000 rpm, and as if these challenges weren't daunting enough, they must also combat the arid atmosphere prevalent at lofty altitudes.

Through years of tireless innovation, we have harnessed the power of Metcar® graphites to conquer these extreme conditions. Our groundbreaking graphites have been specially developed to endure higher temperatures, drier atmospheres, and elevated speeds and loads, all while possessing superior lubricating properties. These exceptional materials utilize a robust carbon matrix as their structural foundation, complemented by the unmatched lubricating capabilities of graphite. Furthermore, the carbon matrix can be impregnated with a diverse array of elements, thereby enhancing and bestowing entirely novel properties upon the material.

Thanks to our material's unique layered structure and exceptional characteristics, it outlasts alternative bearing and seal materials, making it the quintessential choice for mechanical components that optimize aircraft performance at its zenith.

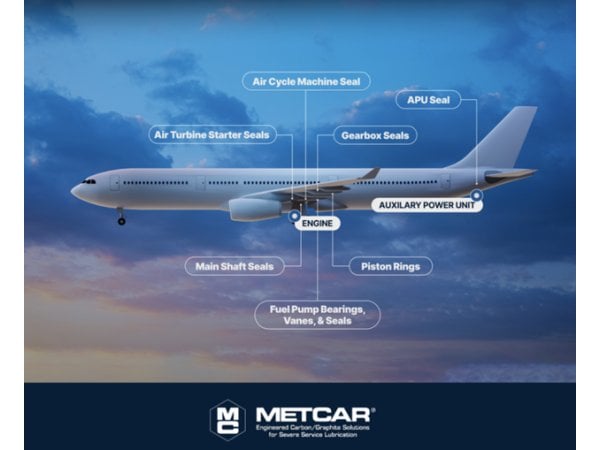

Our unrivaled materials find widespread application as bearings and seals in crucial aerospace components, including:

Discover more about how we empower aerospace engineers to push the boundaries of what is possible by visiting: https://blog.metcar.com/graphite-pushes-limits-aerospace