In the world of commercial aviation, performance and efficiency are key. Carbon graphite is revolutionizing the industry by offering lightweight, durable solutions that reduce operational costs and...

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726.

Aviation Week Marketplace is part of the Informa Markets Division of Informa PLC

Save this service to your Saved Items and return to it later.

Metcar's advanced graphite material is transforming aerospace engineering. It withstands extreme conditions—temperatures over 1,000 degrees—essential for safety and performance. Its self-lubricating nature extends aircraft longevity, optimizes fuel efficiency by managing high engine temperatures, and reduces overall weight, cutting operating costs significantly.

Our innovative graphite solutions provide unparalleled reliability for mechanical components, crucial for maintaining peak aircraft performance. This leads to longer service intervals and better fuel economy, giving airlines a competitive edge in operational efficiency and financial flexibility.

With Metcar's graphite, aerospace engineers can push the limits of technology, ensuring aircraft not only meet but exceed the rigorous demands of modern aviation. It's the material that elevates, empowers, and transforms the aerospace landscape.

View this product at metcar.com

In the world of commercial aviation, performance and efficiency are key. Carbon graphite is revolutionizing the industry by offering lightweight, durable solutions that reduce operational costs and...

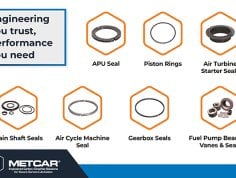

We're at the forefront of aerospace technology, offering unmatched solutions such as air bleed valves, propulsion engine main shaft seals, and piston rings, crafted from custom carbon graphite for...

In the intricate world of aerospace service and repair, choosing between Original Equipment Manufacturer (OEM) and Parts Manufacturer Approval (PMA) parts is a critical decision. At Metcar, we...

The aerospace industry leaves no margin for error, demanding materials that can withstand high altitudes, high speeds, and extreme temperatures upwards of 1,000 degrees to meet the strict safety...

At Metcar, we specialize in advanced carbon graphite solutions that improve component performance, reduce maintenance costs, and extend service life in aerospace applications. Our PMA-approved...