Force gauge with internal measuring cell up to 5 N / various alarm modes / graphic display / data logger / incl. software The force gauge can be used to measure both tensile and compressive forces...

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726.

Aviation Week Marketplace is part of the Informa Markets Division of Informa PLC

Save this service to your Saved Items and return to it later.

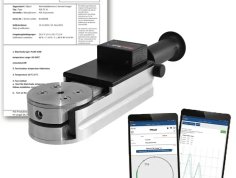

The UCI hardness tester PCE-3500 has been designed for the non-destructive hardness measurement of metallic components. The UCI hardness tester works on the basis of the Ultrasonic Contact Impedance test procedure. This UCI procedure works as follows: a Vickers diamond at the probe is stimulated with its self-resonance. By pushing the probe, the vibration frequency is reduced depending on the hardness of the surface and on the e module of the material and of the contact surface. The hardness of the surface can be determined on the basis of the frequency shift, taking the characteristic curve of the material into consideration.

The UCI hardness tester works non-destructively. There is a microscopically slight pressure against the surface, however, this is normally not visible. Due to the low penetration depth of the Vickers diamond, this UCI hardness tester is especially suitable for edge layer hardened components such as, for example, those that emerge when nitriding or induction hardening. It is typically used for punching tools, presses, thin-walled components, cog wheels, turbine blades, camshafts or weld seams. The UCI hardness tester is also suitable for many other hardness testing applications. It has exchangeable probes with different pressure forces and can therefore cover diverse applications.

After measuring the hardness of a component, the UCI hardness tester PCE-3500 shows different statistical values such as the MAX / MIN values and average values. Moreover, the standard deviation and further coefficients can be determined. A bar chart can be indicated. Since the UCI hardness tester is equipped with an internal memory, the measured data can be evaluated by means of a software.

View this product at www.pce-instruments.com/us/measuring-instruments/test-meters/condition-monitoring-pce-instruments-material-tester-pce-3500-incl.-50n-probe-det_6020488.htm

Force gauge with internal measuring cell up to 5 N / various alarm modes / graphic display / data logger / incl. software The force gauge can be used to measure both tensile and compressive forces...

The industrial borescope has a 1.2 m / 3.9 ft long endoscope cable. With a diameter of only 2 mm, cavities with the smallest access can be viewed with the help of this inspection camera. The camera...

The closing force measuring device is a wireless, electronic measuring device for externally powered doors and gates. Typical use is the final inspection of new systems as well as regular...

The Thickness Gauge has an illuminated and high-contrast OLED display on which the measured values are shown in FN and Fe%. The ferrite content measurement is particularly important for welded...

Force Gage with external pressure load cell up to 50 kN / various alarm modes / graphic display / data logger / incl. software The Force Gage with an external pressure load cell is designed for...