Jet engines are meticulously engineered to withstand the most unforgiving conditions known to modern technology. Within turbines, temperatures soar beyond 1,000°F, shaft speeds reach dizzying...

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726.

Aviation Week Marketplace is part of the Informa Markets Division of Informa PLC

Save this service to your Saved Items and return to it later.

For more than 75 years, Metcar has been a trusted partner to the aerospace industry, delivering advanced self-lubricating carbon-graphite solutions that perform where reliability matters most.

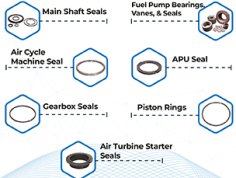

From the main shaft to the auxiliary power unit, Metcar designs and manufactures critical components that ensure safety, efficiency, and performance in flight. Our aerospace-grade materials excel in extreme environments—handling high temperatures, demanding speeds, and the toughest operating conditions.

Our solutions include:

Backed by engineering expertise and decades of proven results, Metcar helps keep fleets in the air and operations running smoothly.

When performance, precision, and trust matter—Metcar delivers.

View this product at metcar.com

Jet engines are meticulously engineered to withstand the most unforgiving conditions known to modern technology. Within turbines, temperatures soar beyond 1,000°F, shaft speeds reach dizzying...

In the intricate world of aerospace service and repair, choosing between Original Equipment Manufacturer (OEM) and Parts Manufacturer Approval (PMA) parts is a critical decision. At Metcar, we...

Metcar's advanced graphite material is transforming aerospace engineering. It withstands extreme conditions—temperatures over 1,000 degrees—essential for safety and performance. Its...

In the intricate world of aerospace service and repair, choosing between Original Equipment Manufacturer (OEM) and Parts Manufacturer Approval (PMA) parts is a critical decision. At Metcar, we...

In the world of commercial aviation, performance and efficiency are key. Carbon graphite is revolutionizing the industry by offering lightweight, durable solutions that reduce operational costs and...